Seawall Secrets: How to Construct a Lasting Coastal Barrier

Why Residential Seawall Construction Protects Your Long Island Waterfront Property

Professional residential seawall construction is the definitive solution for preventing shoreline erosion and protecting your investment from storm damage. For homeowners in Nassau and Suffolk Counties, our expertly installed seawalls preserve land and property value against constant tidal action and storm surges. A properly engineered system from Pearce Marine Construction is designed to last 30 to 60 years, incorporating key components like interlocking panels, a concrete cap, tie-back rods, and deadman anchors. We select the ideal materials—from durable vinyl to robust concrete—to create a permanent barrier customized for Long Island's unique conditions.

Waterfront properties in Southampton, West Hampton, and West Islip face constant threats from coastal storms. Since seawalls are not typically covered by insurance, professional construction is essential from day one. A poorly built wall can fail in 10-15 years, whereas a professionally engineered system will protect your investment for decades.

The process demands marine engineering expertise, proper permitting, and installation techniques custom to Long Island's unique coastal environment. Every detail, from material selection to anchoring, is critical for a structure designed to withstand the force of water.

The Complete Guide to Residential Seawall Construction

For waterfront homeowners from Massapequa to West Hampton, residential seawall construction is essential for safeguarding property from erosion and storm damage. A well-built seawall absorbs wave energy and stabilizes the shoreline, preventing land loss and preserving property value. We guide clients in Nassau and Suffolk Counties through selecting the right materials and design to ensure their coastal barrier is a lasting investment.

Choosing the Right Seawall Material for Long Island

The choice of material is a foundational decision in residential seawall construction, directly impacting its longevity and performance against Long Island's saltwater and weather. We help clients select the right material based on wave action, soil conditions, and budget.

Vinyl Seawalls: A popular choice in Merrick and Wantagh, vinyl is highly resistant to saltwater corrosion, marine borers, and UV rays. With a potential lifespan of 50+ years and minimal maintenance, it offers excellent long-term value. For more details, see our guide on Vinyl Seawall Construction.

Concrete Seawalls: Known for exceptional strength, concrete is ideal for areas with heavy wave action, like the Great South Bay. These engineered structures last 30-50 years and offer robust, long-term protection. Learn more on our Concrete Sea Wall Construction page.

Wood Bulkheads: A traditional, cost-effective option for calmer waters, wood has a shorter lifespan of 15-30 years due to rot and marine borers, requiring more maintenance.

Steel Sheet Piling: Used for projects needing extreme protection, steel offers immense strength but is more common in commercial applications. It is susceptible to saltwater corrosion and requires protective coatings.

When choosing a material for your property in Brightwaters or Babylon, consider the environmental demands, budget, desired aesthetics, and long-term maintenance. Local regulations in Nassau and Suffolk Counties may also influence material choices.

| Seawall Material | Typical Lifespan (Years) | Estimated Cost (Linear Foot) | Maintenance Needs | Aesthetics | Saltwater Corrosion Resistance |

|---|---|---|---|---|---|

| Vinyl | 40-50+ | $200 - $500 | Low | Clean, modern | Excellent |

| Concrete | 30-50 | $300 - $600 | Moderate | Robust, customizable | Good (with proper mix/rebar) |

| Wood | 15-30 | $150 - $400 | High | Natural, rustic | Poor (susceptible to borers) |

| Steel | 30-40 (galvanized) | $400 - $700+ | Moderate-High | Industrial, strong | Poor (without protection) |

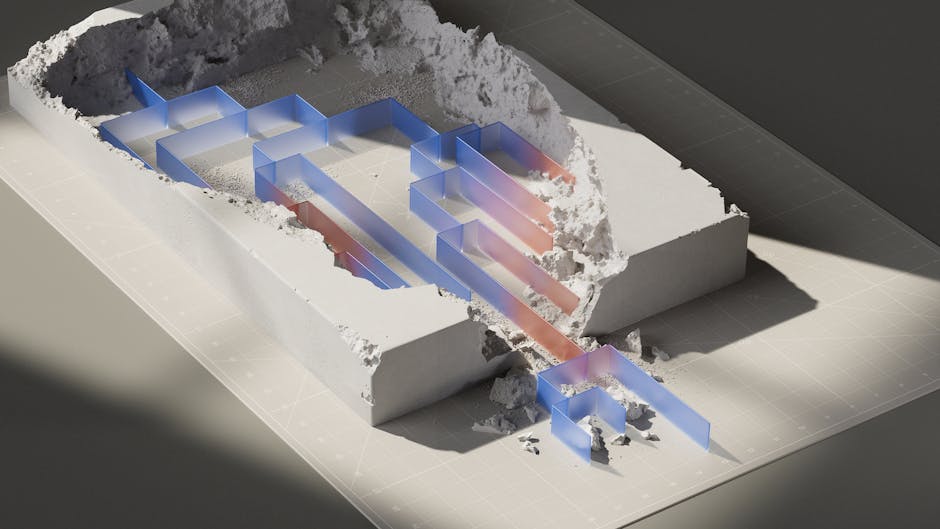

Key Components and Engineering for a Durable Design

A well-engineered seawall is a complex system. Our expertise in residential seawall construction across Long Island, from Cold Spring Harbor to Huntington, ensures every component contributes to the structure's integrity.

The key components of a seawall system include:

- Seawall Panels: The primary vertical barrier (vinyl, concrete, wood, or steel) that blocks waves and retains soil.

- Concrete Cap: A reinforced beam along the top that unifies the panels and provides a finished look.

- Tie-Back Rods & Deadman Anchors: A critical anchoring system where steel rods connect the wall to buried concrete anchors, preventing it from leaning.

- Weep Holes and Drains: Essential drainage features that relieve hydrostatic (water) pressure from behind the wall, preventing failure.

- Walers: Horizontal beams that provide additional support and distribute tension from the tie-back rods across the panels.

Professional engineering is non-negotiable. A certified engineer designs the system based on soil composition, wave forces, and tidal ranges for your specific property. This ensures the seawall is robust enough for Long Island's shorelines and complies with all local building codes in Nassau and Suffolk Counties.

For more on our custom solutions, visit our Seawalls and Bulkheads services page. The FEMA Home Builder’s Guide to Coastal Construction also offers valuable insights.

The On-Site Installation: A Step-by-Step Overview

The installation of a residential seawall is a precise process demanding specialized equipment and skilled craftsmanship. Our team follows a rigorous approach to ensure every seawall we build on Long Island is of the highest quality.

Here's an overview of our on-site process:

- Site Prep and Permitting: We secure all necessary permits and prepare the site by marking the wall's alignment.

- Driving Sheets: Using a drive guide for accuracy, we use a vibratory hammer to methodically drive the interlocking seawall panels to the required depth.

- Installing the Anchor System: We install horizontal walers for support, then secure them to buried deadman anchors with steel tie-back rods.

- Backfilling and Drainage: The area behind the wall is carefully backfilled, and drainage systems like weep holes are installed to relieve water pressure.

- Pouring the Concrete Cap: The final step is pouring a reinforced concrete cap, which ties the system together and provides a rigid, finished top.

Our commitment to professional craftsmanship ensures every step is executed with precision. This meticulous approach is why our seawalls in locations like Bayshore and South Hampton are built to last. Learn more about the professionals behind these projects on our Seawall Construction Companies page.

Signs Your Residential Seawall Needs Professional Repair

Even a robust residential seawall endures wear from Long Island's coastal conditions. Recognizing early signs of damage is key to preventing costly failures. Regular inspections are recommended to identify deterioration.

Look for these common signs that your seawall in West Islip or Babylon needs professional repair:

- Cracks in the Concrete Cap: Large, growing cracks indicate structural stress.

- Leaning or Bowing: A wall leaning toward the water is a serious sign of anchor system failure.

- Sinkholes Behind the Wall: Depressions in your yard suggest soil is washing out through the wall.

- Visible Soil Erosion: Soil loss at the base of the wall means it is no longer retaining the land.

- Rusted Hardware: Corroded tie-backs or other metal components are structurally compromised.

Common causes of failure include tidal erosion, storm damage, and saltwater corrosion. Addressing these issues promptly is critical. For comprehensive solutions, explore our Seawall Repair Services and connect with our expert Seawall Repair Contractors.

Professional Maintenance Services to Maximize Lifespan

To ensure your residential seawall provides protection for 30 to 50 years or more, Pearce Marine Construction offers professional maintenance and inspection services across Nassau and Suffolk Counties. Our services are designed to identify and address potential issues before they lead to costly failures, extending the life of your investment.

Our professional maintenance program includes:

- Scheduled Professional Inspections: Our experts conduct thorough inspections to assess structural integrity, identify subtle signs of stress or soil loss, and check for cracks or corrosion.

- Weep Hole and Drainage Clearing: We ensure all drainage systems are clear of debris to properly relieve hydrostatic pressure, a leading cause of seawall failure.

- Crack and Spall Repair: Our team professionally seals cracks in concrete caps or panels to prevent water intrusion and further deterioration.

- Runoff and Grading Assessment: We evaluate your property's drainage to ensure runoff is properly managed away from the seawall, preventing soil saturation and excess pressure.

Partnering with us for proactive maintenance protects your Long Island property for decades. For expert service on your existing structure, see our Bulkhead Repair Long Island services.

Budgeting and Finalizing Your Seawall Project

Investing in residential seawall construction is a significant decision that protects the long-term value and stability of your waterfront property in Nassau or Suffolk County. At Pearce Marine Construction, we provide transparent planning to ensure you understand the project's scope, costs, and value. As a woman-owned marine construction company with generational expertise, we don't just build seawalls—we forge lasting coastal barriers.

Ready to secure your waterfront property? Contact us for your expert seawall consultation today.

Understanding the Costs of Residential Seawall Construction

Seawall pricing varies based on several factors. On average, a residential seawall costs $150 to $600 per linear foot, with typical projects in areas like Merrick or Huntington ranging from $15,000 to $60,000. Commercial or high-erosion zone projects can be significantly more.

Key factors influencing cost include:

- Material Choice: Wood, vinyl, concrete, and steel have different price points and installation requirements.

- Project Size: The length and height of the wall directly impact material and labor costs.

- Site Accessibility: Difficult access for heavy machinery can increase logistical costs.

- Soil Conditions: Hard or rocky soil may require specialized equipment, affecting the price.

- Permitting and Labor: Fees for permits and the complexity of the installation contribute to the final cost.

It is also important to weigh the cost of repair vs. replacement. While a minor repair may seem cheaper, a full replacement is often a better long-term investment, providing a brand-new structure with a full lifespan and peace of mind. A new, expertly constructed seawall is an investment that secures your property. For a more detailed breakdown, visit our Cost of a Seawall page.

Bring Your Vision to Life

Whether you're planning a custom dock, seawall, or boat lift, our experienced team is ready to deliver high-quality marine construction tailored to your needs. Pearce Marine Construction brings craftsmanship, precision, and a deep understanding of Florida’s waterways to every project. Let us help you create a durable, beautiful solution that stands the test of time. Get in touch now for a personalized estimate!